The following is a basic set of instructions and photos from my 1987 924s.

This car does not have air bags and I have a Dino Wheel so your car may be

different.

Ok lets get started. First off you will be dealing with allot of

little screws. Make sure that you have a container to put them in as you

take things apart. It is also important to lay things out in order as you

remove then as it is easy to leave something out during the reassembly

Tools that you will need:

Phillips screwdriver #1 Tip (smallest of the standard sizes)

Metric Allen wrench set

Couple of various sized flat screwdrivers

Small pry-bar

Hammer

Brass drift or large deep dish socket

Small scribe or small coal chizzes to mark location of the wheel relative

to the steering column

You may need a Steering wheel puller

Good Shop Light.

Lets Get Started

Here is my steering wheel. Note that it is centered and double check that

the wheels are strait.

Here is a couple of photos of the left and right sides

To remove my wheel I have to take the six Allen bolts out in the center of

the wheel. THIS IS NOT THE SAME AS A STOCK STEERING

WHEEL. Please reference the cars shop manual for instructions

Once the wheel is free you have to disconnect the Wires for the horn.

THIS IS NOT THE SAME AS A STOCK STEERING WHEEL

Next remove the rubber boot from around the adaptor/crush zone.THIS

IS NOT THE SAME AS A STOCK STEERING WHEEL

On my set up there is a marking for where the "TOP" should be. If

you have not done it already make sure your wheel is centered.

THIS IS NOT THE SAME AS A STOCK STEERING WHEEL

Next remove the center nut. This may requite some muscle Mine comes

off rather easy. I put a large screwdriver through the adaptor bracket and

hold it while I take the nut off with a socket. Take the nut and washer of

but DON'T TAKE THE ADAPTOR / WHEEL OFF YET. THIS IS NOT

THE SAME AS A STOCK STEERING WHEEL

Once the nut and washer are off you have to scribe the shaft and the

adaptor. On the stock wheel you will be scribing the wheel. The mark on

the adaptor is hard to see but it is there. Note the mark on the steering column

Once you mark or index the parts you can continue taking it apart.

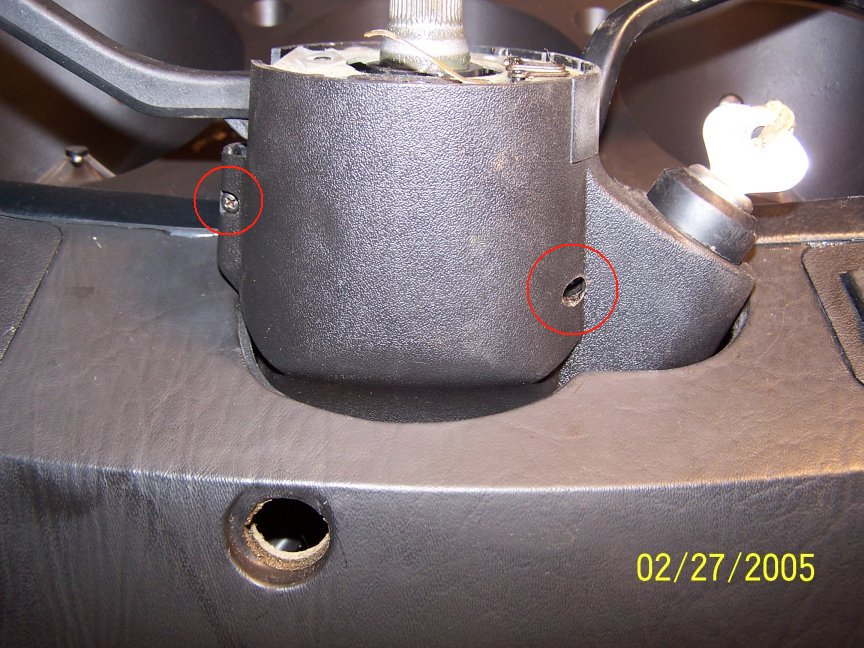

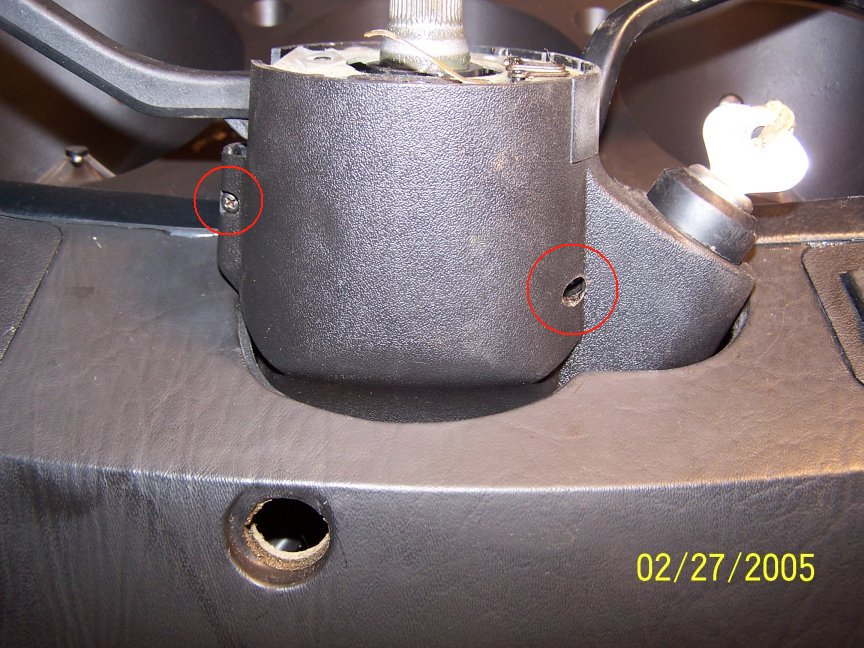

Now you are looking at the top of the switches / stalks. There are

three flat head screws that have to be removed.

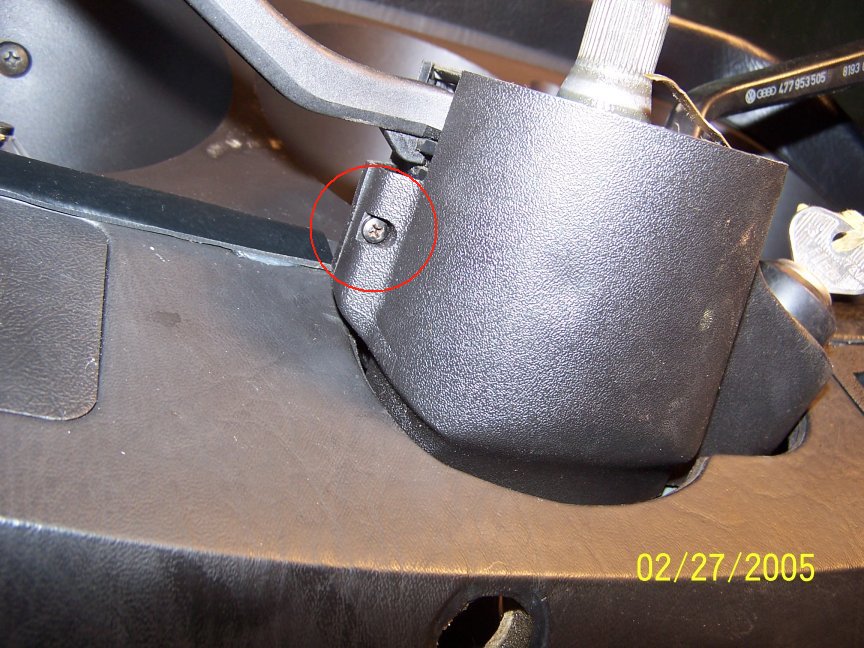

Now that you have removed the screws the stalks will be loose. You

now have to remove the plastic housing around the stalks. It splits

longitudinally and is held in place with two screws that are from below. The

reason I did not remove this first is it is easier with the wheel removed and

with the stalks loose it is easier to remove the plastic pieces. Here are a

couple of photos showing the screw locations looking up from below.

Here is a photo of the two screw note that they are two different sizes

Now it is time to CAREFULLY slide the stalks off the column. There

are a bunch of wires connected to the switches. In my car I don't have to

remove them. I carefully pull them forward from underneath as I gently pull on

the switches out. You will also note that the two stalks / switches can

separate from each other. If this happens it is ok. Just carefully

continue to pull/guide the wires out until the switch clearers the steering

column. Repeat the process with the second one. If the two

switches came apart I then CAREFULLY put the two switches back together once

they are removed.

The photo above shows the top switch removed

The photo above shows the bottom switch removed

Both switches removed and reassembled. Note that I still have the wires

attached. You could remove the wires but I prefer to do it this way because if

you forget to hook up a wire that happens to pull back through the dash it will

be a real pain to attach it after you put it all back together.

Another photo of the two switches.

THis is what you should now have left.

Note the three little holes that are where the three screws went

that hold the switches. These can be broken off very easily. DO NOT

PRY/LEAN or hang anything from these. If you brake any of these you will

have to replace the whole piece. A couple of other things to note ate the

bearings around the column and the Allen head bolt that is visible on the

left side of the column.

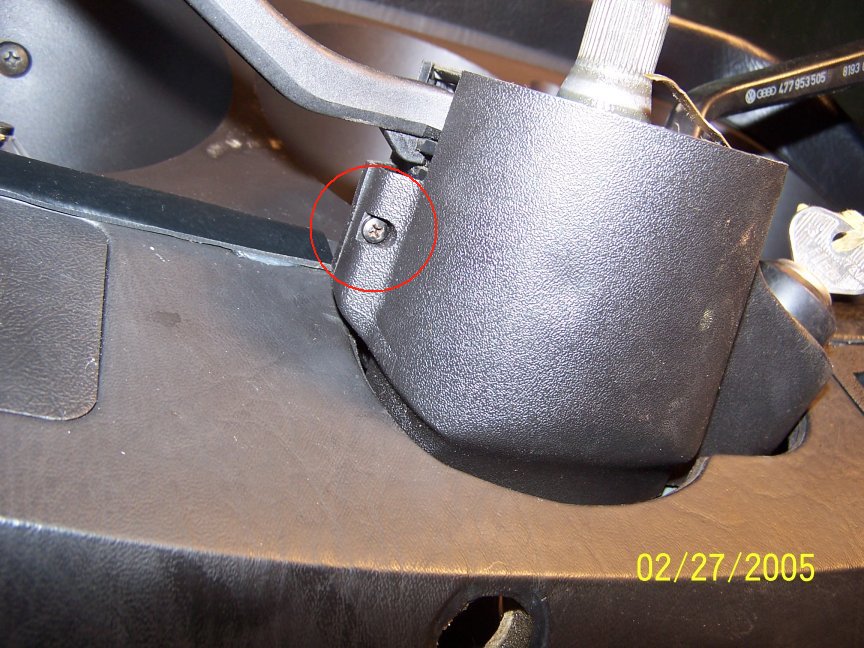

Here is another photo from the side. The next thing to remove is the

plastic collar that is around the steering column. To get this off I pry

gently but firmly in the slots around the bottom. Once it moves a little I

switch to a small pry bar that is thicker and wider than my largest screwdriver

and carefully work it off. DO NOT PRY ON ANY OF THE THREE SMALL SCREW HOLE'S AS

THEY WILL BRAKE OFF.

The piece that my screwdriver is touching is what you want to remove.

The piece removed

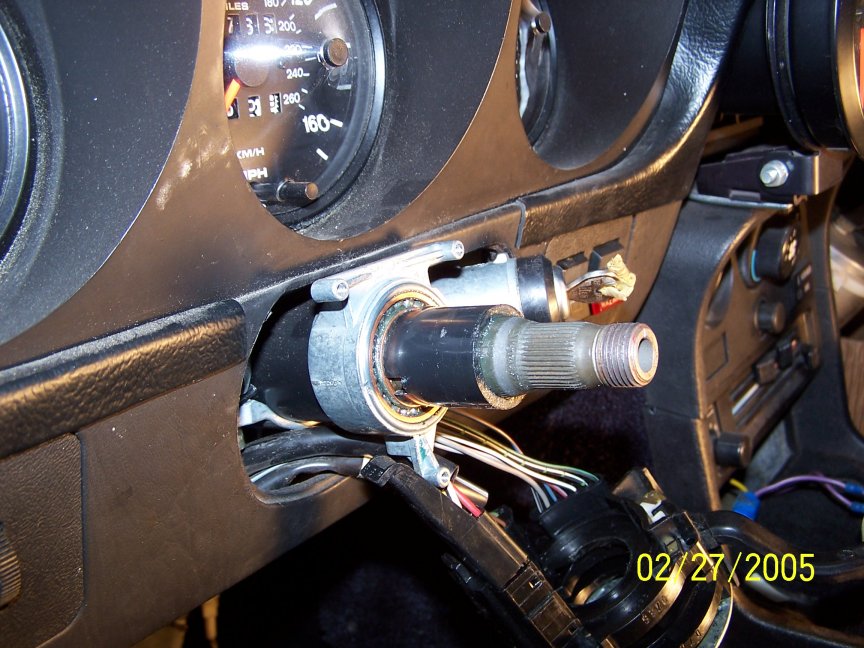

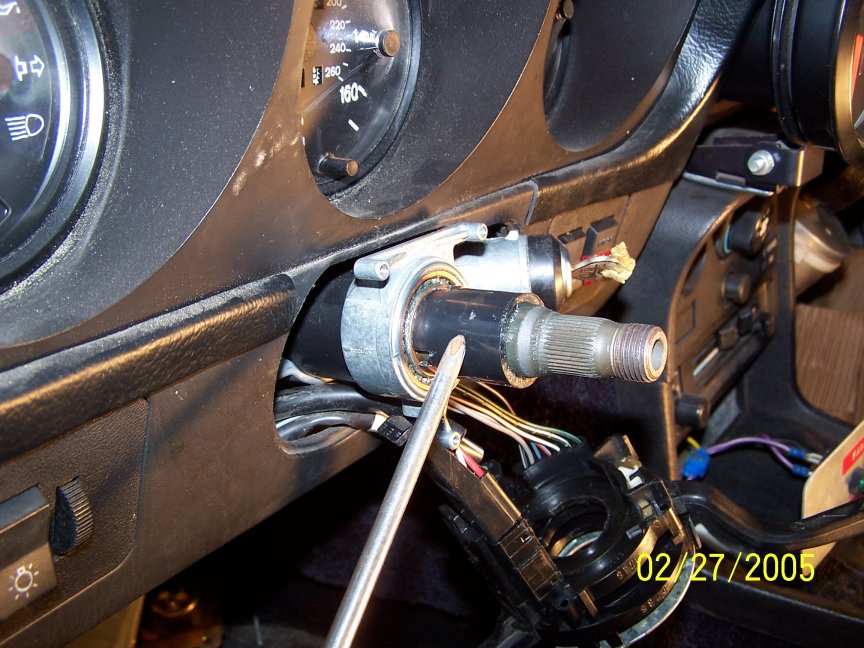

Now you have to remove the Allen head bolt on the left side of the

columne.

You get at this through a whole in the bottom of the dash.

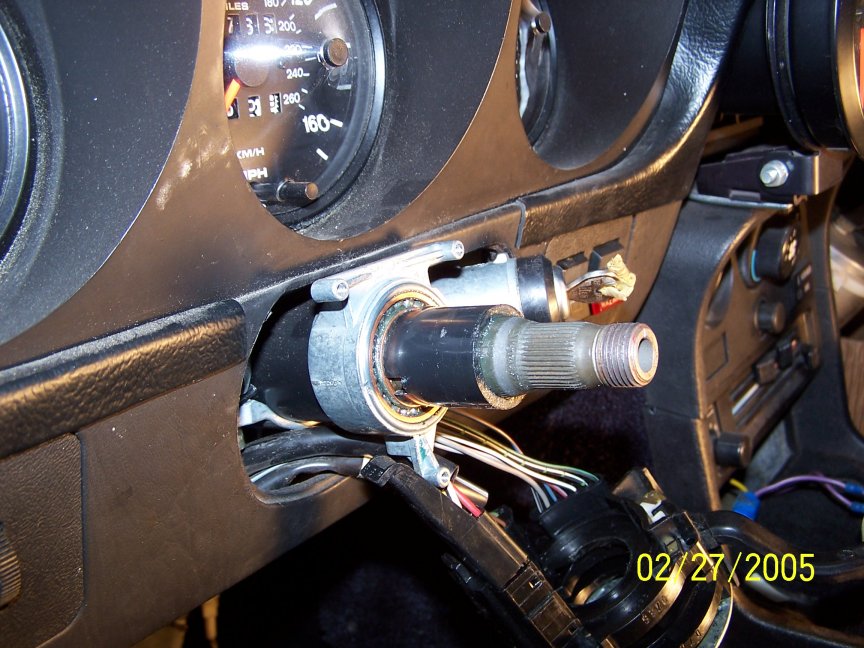

With this bolt removed the asemble with the ignition switch will slide

out. Note that there are a bunch of wires attached to the back of the

switch.

Unplug the wires from the back of the ignition switch

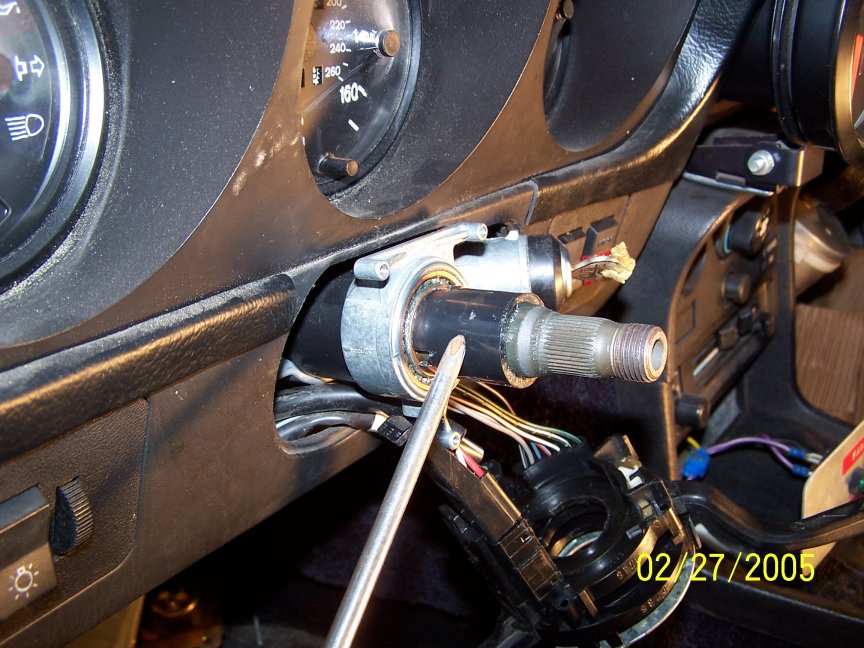

Now flip the piece over and look at the back where the wires were plugged

in and you will see a small Phillips screw. Remove this and the switch

will slide out.

Here is the unit with the screw removed

You can then slide the switch out

On my new switch I put some grease on the end of the switch where the tang

from the lock engages as this will se allot of ware.

You are now ready start the re assembly. I will not cover the whole

thing just a couple of highlights.

When I put the bracket back I packed the bearings with fresh grease.

the plastic ring/spacer will get some burs on it. I lightly sand /

file them off befor I reinstall it. I also put a light coating of grease

inside to aid in it slipping back on. When reinstalling this do not use a

screwdriver and a hammer to tap it in place. It will damage the plastic or

even split it. I use a large deep socket and tap on it alternating forum

side to side.

When I install the plastic trim pieces I again do this with the switches

in place but not screwed in place. this will give you a little play when

you put the trim pieces back on. In the following photo you will se how I

place the top trim piece. I then push it down and back in place. It

should just snap in place.

Well that about covers it. I hope this helps